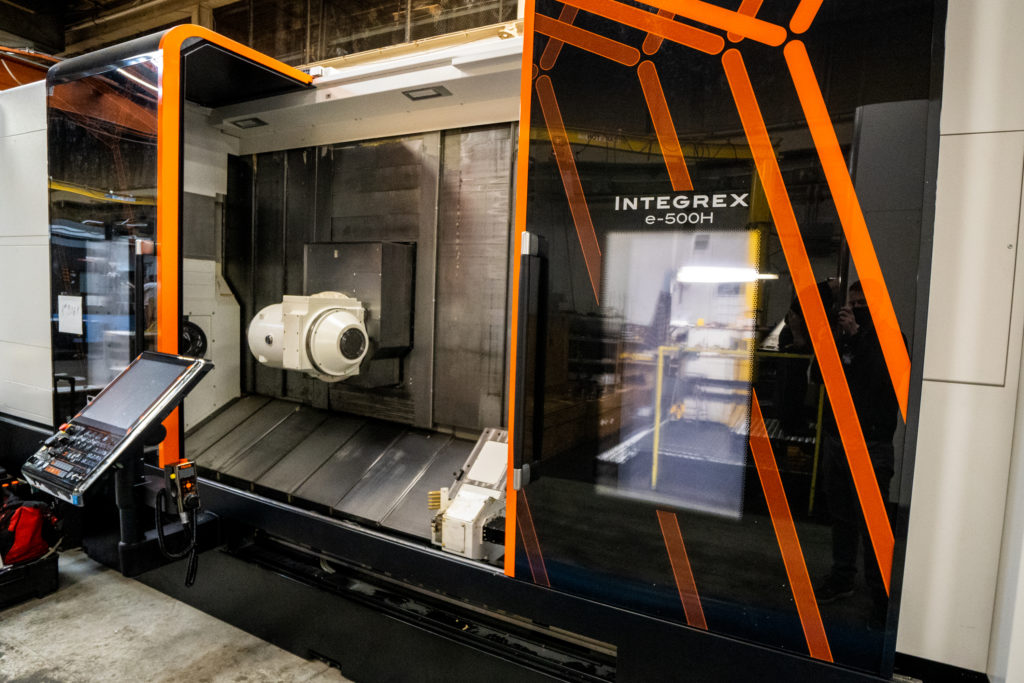

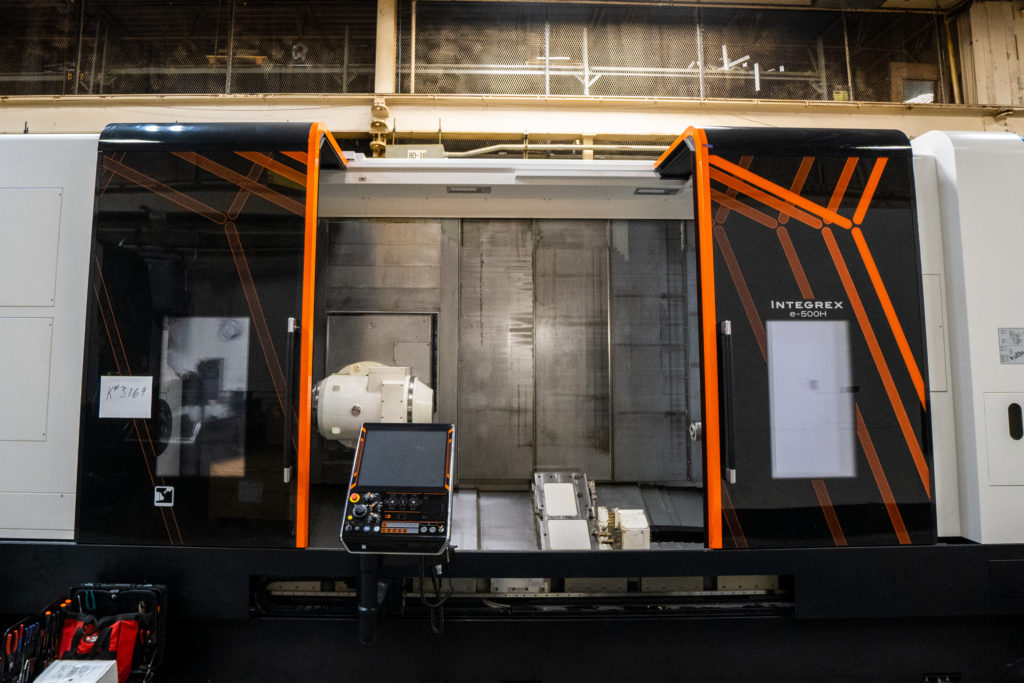

Kurt Machining is completing installation of the industries most advanced Multi-tasking machining center from Mazak. The Integrex e-500H Multi-Tasking Machining Center will increase our capacity and allow for single-setup operations including turning, milling, boring, and drilling of parts 32” in diameter and up to 120” in length. This machine is perfect for large-diameter, highly-complex parts that service the defense and aerospace industries.

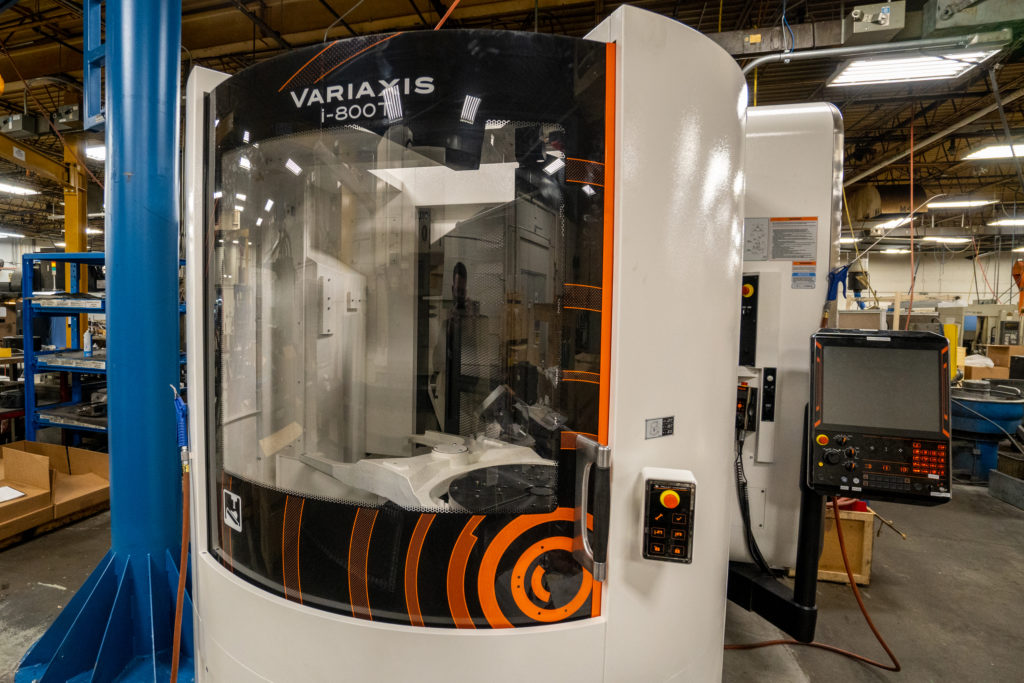

Our Machining Division also recently implemented a VARIAXIS i-800T into its operations that combines multiple-surface, simultaneous 5-axis milling with advanced turning capabilities that will allow us to manufacture highly complex parts in single setups. Its unique trunnion-style tilting table features a 50-taper spindle and multi-tasking operations. This greatly reduces the possibility for errors that arise from multiple setups.

Integrex e-500H Characteristics:

- Milling spindle B-axis travel -30 ~ 210 degrees (.0001 degree min index angle)

- 40HP 7.2” spindle bore

- Completely programmable servo-driven steady rests

- Full 5-axis contouring

- 80 automatic tool changer

- 40″ long boring bar stocker (2-bar) for deep boring applications

Variaxis i-800T Characteristics:

- Handles parts up to 39.37″ in diameter and 14.76″ high

- DONE IN ONE® operations reduce production lead times

- Trunnion-style tilt table reduces setup and change-out times

- High-speed rapid traverse rates and rotary axes indexing